- 2025-11-27

- 170

- 5 Comments

Key Mold Spare Parts: Their Roles and Why Quality Matters

Not all mold spare parts are the same—each plays a unique role in mold function, and their quality directly impacts performance. Below are the most critical mold spare parts and why investing in high-quality versions is essential:

1. Ejector Pins & Sleeves: The "Workhorses" of Part Removal

Ejector pins and sleeves are responsible for pushing finished parts out of the mold cavity after each cycle. They endure constant friction, impact, and exposure to high temperatures—making them one of the most frequently replaced mold spare parts.

Why Quality Counts: Low-quality ejector pins are prone to bending, breaking, or wearing down quickly. This can lead to:

Stuck parts in the mold (causing costly downtime to disassemble and remove parts).

Scratches or damage to part surfaces (ruining finished products).

Uneven ejection force (resulting in part deformation).

Our High-Quality Solution: Our ejector pins are made from premium H13 hot-work steel or S136 corrosion-resistant steel, heat-treated to HRC 58–62 for maximum durability. They feature a precision-ground surface finish (Ra ≤ 0.2μm) to reduce friction and prevent part damage. For a packaging manufacturer, our ejector pins lasted 3x longer than standard alternatives, cutting replacement frequency and downtime by 67%.

2. Guide Pins & Bushings: Ensuring Precise Mold Alignment

Guide pins and bushings align the fixed and moving halves of the mold, ensuring that the cavity and core meet perfectly every cycle. Even a tiny misalignment (as small as 0.001mm) can ruin parts or damage the mold.

Why Quality Counts: Poorly made guide pins or bushings with inconsistent dimensions cause:

Mold misalignment (leading to flash, part misfit, or cavity damage).

Excessive wear on mold surfaces (shortening mold lifespan).

Noisy mold operation (indicating friction and potential damage).

Our High-Quality Solution: Our guide pins are manufactured with 5-axis CNC grinding, achieving dimensional tolerances of ±0.0005mm. We use 316L stainless steel for corrosion resistance and apply a PTFE coating to reduce friction. For an automotive component supplier, our guide pins eliminated mold misalignment issues, reducing defect rates by 55% and extending mold life by 25%.

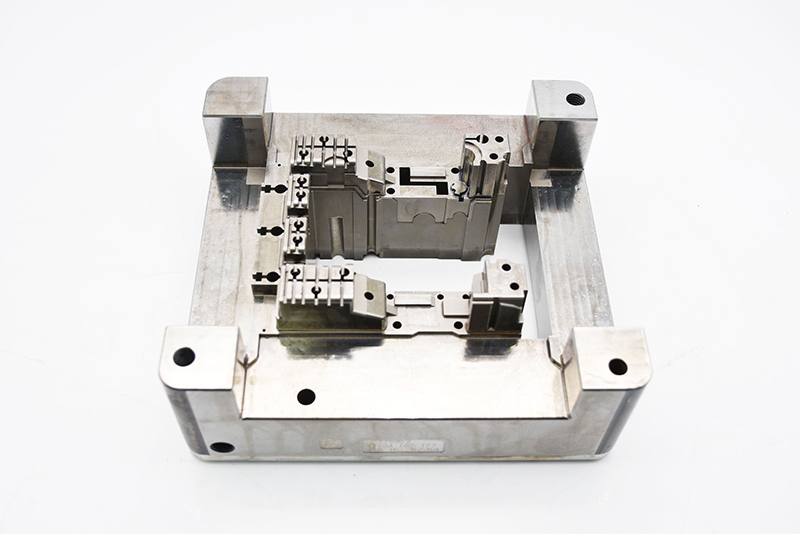

3. Sprue Bushings & Nozzles: Controlling Material Flow

Sprue bushings connect the mold to the injection molding machine’s nozzle, guiding molten material into the mold cavity. They must withstand high pressure and temperature, and maintain a smooth inner surface to prevent material buildup.

Why Quality Counts: Low-grade sprue bushings often have rough inner surfaces or inconsistent hole diameters, leading to:

Material flow restrictions (causing incomplete part filling).

Plastic buildup (resulting in black spots or contamination on parts).

Premature wear (requiring frequent replacement).

Our High-Quality Solution: Our sprue bushings are made from H13 steel with a polished inner surface (Ra ≤ 0.1μm) to ensure smooth material flow. They feature a heat-resistant coating to withstand temperatures up to 300°C, and their precision-machined nozzle interface ensures a tight seal—preventing material leakage. A consumer electronics manufacturer reported a 70% reduction in material-related defects after switching to our sprue bushings.

4. Cooling System Components: Maintaining Part Quality & Cycle Time

Cooling system components—such as water valves, O-rings, and cooling inserts—control the temperature of the mold, ensuring that parts cool evenly and solidify correctly. Poor cooling leads to warpage, sink marks, and longer cycle times.

Why Quality Counts: Inferior cooling components cause:

Leaks (damaging electrical systems or causing mold rust).

Uneven cooling (resulting in part defects or longer cycle times).

Valve failure (disrupting cooling flow and halting production).

Our High-Quality Solution: Our cooling valves are made from brass with a corrosion-resistant nickel plating, and our O-rings use medical-grade silicone to withstand high temperatures and chemicals. We also offer custom cooling inserts with micro-channels for precise temperature control. For a medical device manufacturer, our cooling system components reduced cycle time by 20% and eliminated cooling-related defects (such as sink marks) entirely.

Our Mold Spare Parts: Built for Reliability and Performance

What sets our mold spare parts apart from generic alternatives? It’s our unwavering focus on quality, precision, and durability—designed to meet the demands of modern manufacturing:

1. Premium Materials & Advanced Manufacturing

We use only industry-proven materials for our mold spare parts, including H13 steel (for high-temperature resistance), S136 steel (for corrosion resistance), 316L stainless steel (for hygiene-critical applications), and medical-grade polymers (for seals and gaskets). Our manufacturing processes include 5-axis CNC machining, wire EDM, and precision grinding—ensuring every part meets strict dimensional standards.

2. Rigorous Quality Control

Every mold spare part undergoes 100% inspection before delivery. We use advanced testing equipment, including CMM (Coordinate Measuring Machines) for dimensional accuracy, surface roughness testers, and hardness testers (to verify heat treatment). This ensures that every part meets or exceeds industry standards (such as ISO 9001 and IATF 16949 for automotive applications).

3. Customization for Unique Needs

Not all molds are the same—we offer custom mold spare parts tailored to your specific mold design, material requirements, and production conditions. Whether you need a custom-length ejector pin, a specialized cooling insert, or a high-temperature sprue bushing, our engineering team works with you to design and manufacture parts that fit perfectly and perform reliably.

4. Fast Delivery & Inventory Support

We understand that downtime waits for no one. We maintain a large inventory of standard mold spare parts, offering same-day shipping for urgent orders. For custom parts, we provide fast lead times (2–5 days for most designs) and can help you set up a managed inventory system—ensuring you always have the parts you need, when you need them.

Related Posts

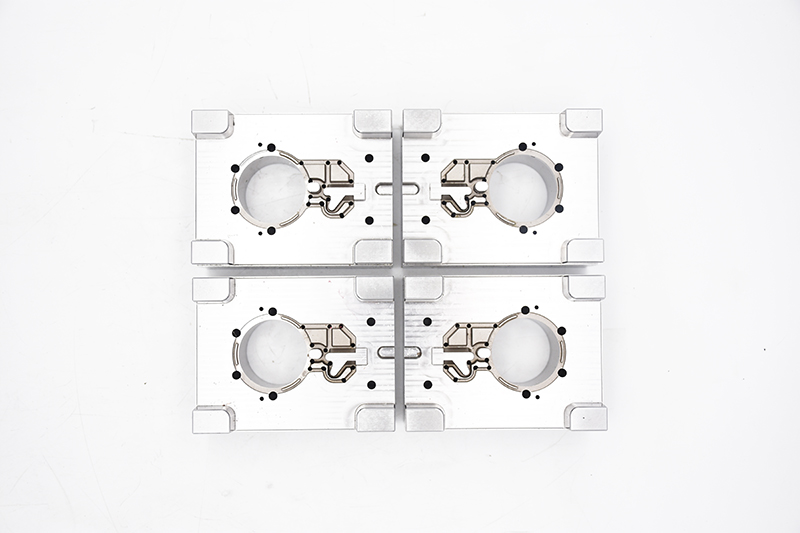

- Precision Irrigation mold cavity and spare parts

- zefu-mold

- 1139