- 2025-12-01

- 174

- 5 Comments

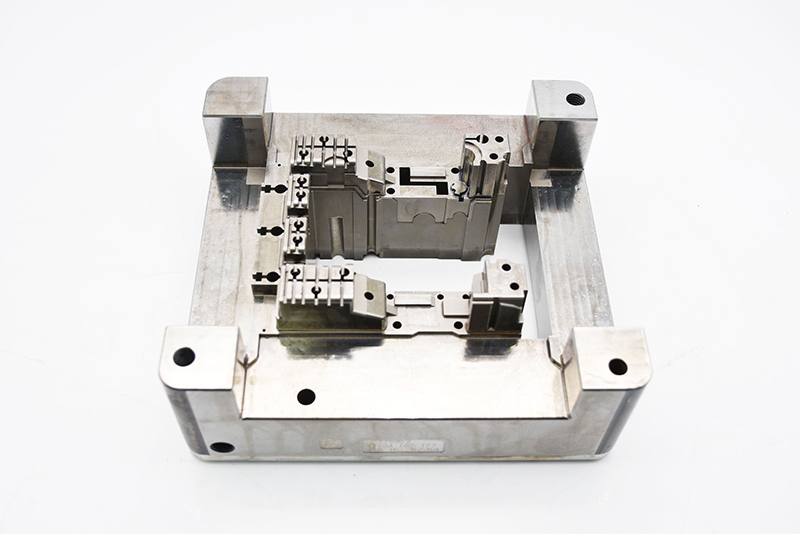

Precision Mold Parts Quality: The Hidden Driver of Your Manufacturing Profitability

In the competitive world of manufacturing, profitability often hinges on details that go unnoticed—until they go wrong. Precision mold parts are one such detail. Low-quality parts may seem like a cost-saving choice upfront, but they quietly erode profits through downtime, scrap, and lost customers. On the other hand, high-quality precision mold parts act as a profit driver: they keep lines running, reduce waste, and ensure your products meet the standards that win repeat business. For manufacturers aiming to build sustainable profitability, quality in mold parts isn’t an option—it’s the foundation of every successful production cycle.

Why “Cheap” Mold Parts Cost You More in the Long Run

It’s tempting to opt for lower-cost precision mold parts to cut immediate expenses. But the true cost of these parts reveals itself over time, in ways that harm your bottom line far more than the initial savings:

A

50genericejectorpinthatbreaksafter100,000cyclescancause8hoursofdowntime(costing

4,000 in lost production) and require emergency shipping for a replacement (adding $200).A poorly machined guide bushing that misaligns the mold can create 10% scrap rates—for a manufacturer producing 10,000 parts per day at

2each,that’s

4,000 in wasted materials daily.A subpar sprue bushing that leaks plastic can contaminate an entire batch of medical devices, leading to a recall that costs $100,000+ and damages your brand reputation.

These aren’t hypothetical scenarios—they’re real challenges our clients faced before switching to our quality precision mold parts. The difference? Our parts are engineered to avoid these costly pitfalls, turning “hidden costs” into “hidden profits.”

Quality Precision Mold Parts: Engineered for Your Industry’s Unique Demands

Every manufacturing sector has distinct challenges—from the high-temperature demands of automotive molding to the sterility requirements of medical devices. Our quality precision mold parts are tailored to meet these industry-specific needs, ensuring optimal performance where it matters most.

1. Automotive Manufacturing: Withstanding Heat, Pressure, and Volume

Automotive production demands mold parts that can handle continuous high-volume cycles (often 24/7) and resist the heat of engineering plastics like ABS and PC/ABS. Our automotive-grade precision mold parts are built to rise to this challenge:

Case Study: EV Battery Bracket Manufacturer: A client producing aluminum-alloy battery brackets for EVs struggled with warped parts and frequent cooling insert failures. Their previous inserts (made from low-grade steel) corroded quickly, leading to uneven cooling and 7% scrap. We supplied cooling inserts made from H13 steel (heat-treated to HRC 58-60) with precision-drilled micro-channels (0.6mm diameter) for uniform heat distribution. The result? Scrap rates dropped to 0.8%, cooling insert lifespan increased from 3 months to 18 months, and annual savings reached $95,000.

Key Advantage: Our automotive parts comply with IATF 16949 standards and are tested to withstand temperatures up to 350°C and pressure up to 2,000 bar—ensuring consistent performance even in the most demanding production environments.

2. Medical Device Manufacturing: Sterility, Traceability, and Biocompatibility

Medical device manufacturing has zero tolerance for contamination or inconsistency. Our quality precision mold parts meet the strictest standards (ISO 13485, FDA QSR 820) to ensure patient safety and regulatory compliance:

Case Study: Disposable Syringe Producer: A manufacturer of 1mL disposable syringes faced repeated FDA scrutiny due to minor burrs on syringe barrels—caused by low-quality ejector pins that left scratches during demolding. Our ejector pins, made from medical-grade 316L stainless steel and polished to Ra ≤ 0.005μm, eliminated burrs entirely. Additionally, each pin came with a unique traceability code linked to material certificates and sterilization test results. The client passed their next FDA audit with no findings, expanded production by 30%, and reduced rejected batches by 90%.

Key Advantage: Our medical-grade parts are produced in Class 8 cleanrooms, coated with biocompatible materials (like PTFE), and undergo gamma radiation resistance testing—ensuring they meet the sterility and safety requirements of even the most critical medical applications.

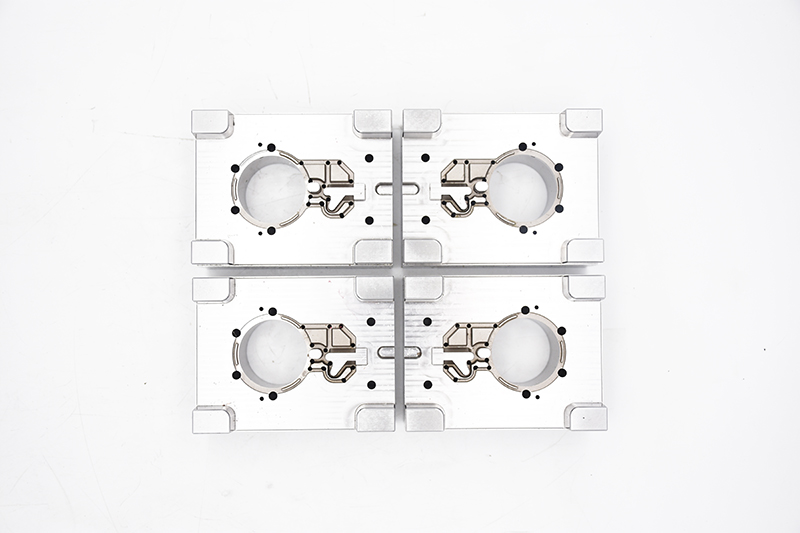

3. Consumer Electronics Manufacturing: Miniaturization and Precision

Consumer electronics demand mold parts that can produce tiny, intricate components (e.g., smartphone camera modules, wearable device sensors) with micron-level accuracy. Our precision parts excel in this space:

Case Study: Smartwatch Sensor Producer: A client making 2mm-diameter pressure sensors for smartwatches struggled with inconsistent sensor performance due to misaligned mold cores—caused by generic guide pins with loose tolerances (±0.002mm). We supplied high-precision guide pins with a tolerance of ±0.0002mm, machined using wire EDM for perfect concentricity. Sensor performance consistency improved from 85% to 99.5%, reducing customer returns by 80% and helping the client secure a major order from a top electronics brand.

Key Advantage: Our micro-precision parts are manufactured with 5-axis CNC machining and laser calibration, achieving tolerances as tight as ±0.0001mm—ideal for the miniaturized components that define modern consumer electronics.

4. Packaging Manufacturing: Speed and Durability

Packaging production runs at high speeds (often 1,000+ parts per minute) and requires mold parts that can withstand constant wear. Our quality parts keep up with this pace:

Case Study: Plastic Food Container Maker: A producer of 500mL plastic food containers faced weekly downtime due to worn valve gates—each failure halted their 24/7 production line for 6 hours. Our valve gates, made from DC53 steel (hardened to HRC 62-64) and coated with TiCN for wear resistance, lasted 12 months (up from 2 months for generic gates). Downtime from valve gate replacement dropped to once per year, saving the client $120,000 annually in lost production and replacement costs.

Key Advantage: Our packaging-focused parts are designed for high-cycle applications, with surface treatments that reduce friction by 60%—extending lifespan and minimizing the need for maintenance.

Our Quality Difference: What Makes Our Precision Mold Parts Stand Out

Not all “quality” mold parts are created equal. Our parts are distinguished by a commitment to excellence that spans every stage of production:

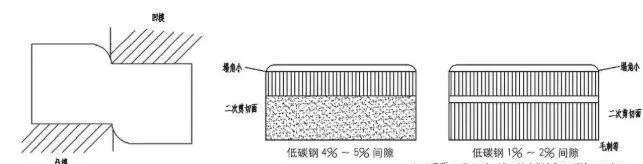

1. Material Excellence: No Compromises

We source only the highest-grade materials from certified suppliers, with each batch tested for:

Chemical purity (to avoid impurities that cause brittleness or corrosion).

Mechanical strength (tensile, compressive, and impact resistance).

Compatibility with industry-specific requirements (e.g., biocompatibility for medical, heat resistance for automotive).

Whether it’s S136 steel for corrosion resistance, H13 steel for heat tolerance, or medical-grade PEEK, we never substitute inferior materials to cut costs.

2. Advanced Quality Testing: Beyond Basic Inspection

Our quality control process goes far beyond checking dimensions—it validates real-world performance:

Environmental Testing: Parts are exposed to extreme temperatures, humidity, and chemicals to simulate years of use.

Wear Simulation: High-stress parts (like valve gates) undergo 100,000+ cycle tests to ensure they maintain performance.

Contamination Testing: Medical-grade parts are tested for particle shedding and chemical leaching to ensure sterility.

This rigorous testing ensures our parts don’t just meet specs—they exceed expectations in real production.

3. Customization with Quality: Tailored to Your Needs

We don’t force you to choose between customization and quality. Our engineering team works with you to design custom mold parts (e.g., unique cooling inserts, specialized ejector pins) that meet your exact requirements—without sacrificing precision or durability. For example, we designed a custom sprue bushing with a tapered inner hole for a client producing plastic tubes, reducing material waste by 15% while maintaining the part’s quality standards.

Partner with Us for Profitable, Quality-Driven Manufacturing

At the end of the day, precision mold parts quality is about more than “good components”—it’s about building a manufacturing operation that’s efficient, reliable, and profitable. We’ve helped hundreds of manufacturers across industries transform their production by eliminating hidden costs and unlocking new revenue opportunities through quality.

Our commitment to your success includes:

Fast Delivery: We maintain a large inventory of standard parts for same-day shipping, and custom parts are delivered in 2-4 weeks.

Technical Support: Our engineers provide on-site assistance to optimize mold performance and troubleshoot issues.

Long-Term Partnerships: We don’t just sell you parts—we work with you to continuously improve your production processes and reduce costs.

If you’re tired of the hidden costs of low-quality mold parts and ready to build a more profitable manufacturing operation, contact us today. Let’s show you how quality precision mold parts can turn your production challenges into competitive advantages.

Related Posts

- Precision Irrigation mold cavity and spare parts

- zefu-mold

- 1139