Engineers telephone 24 hours communication service.

Welcome To Zefu Mold

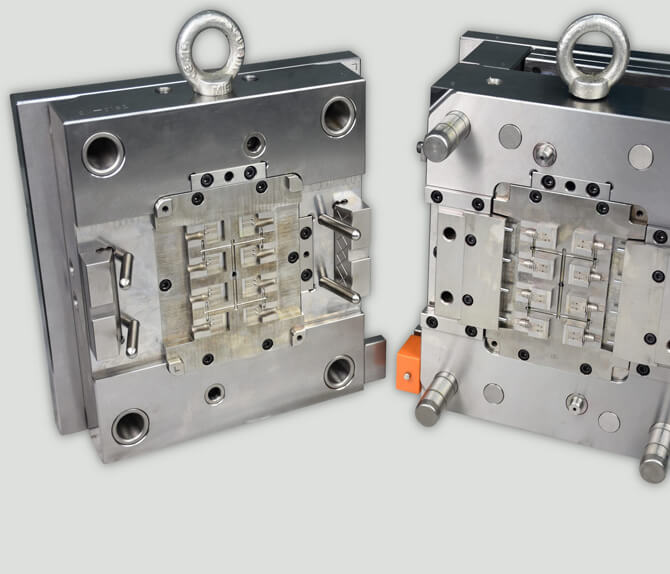

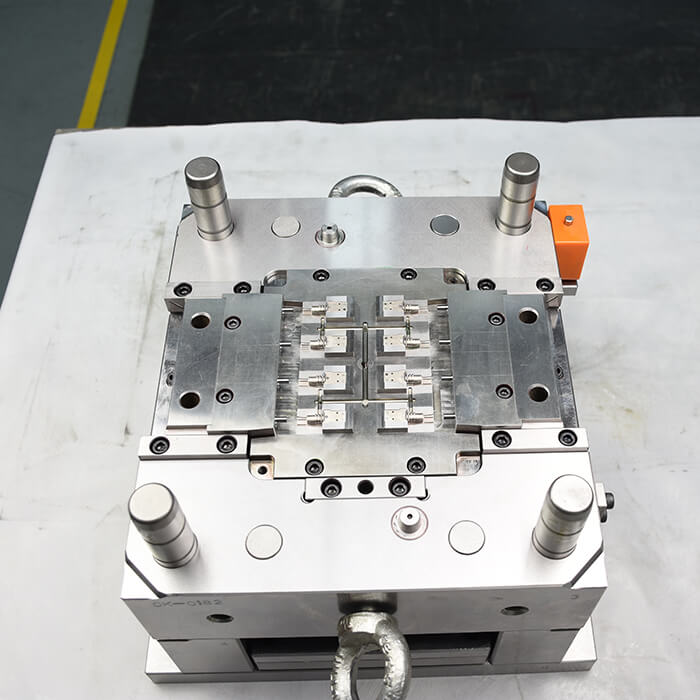

We’re Best Providing

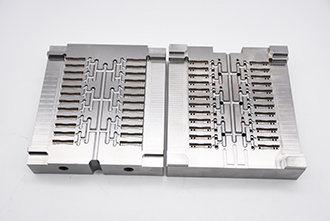

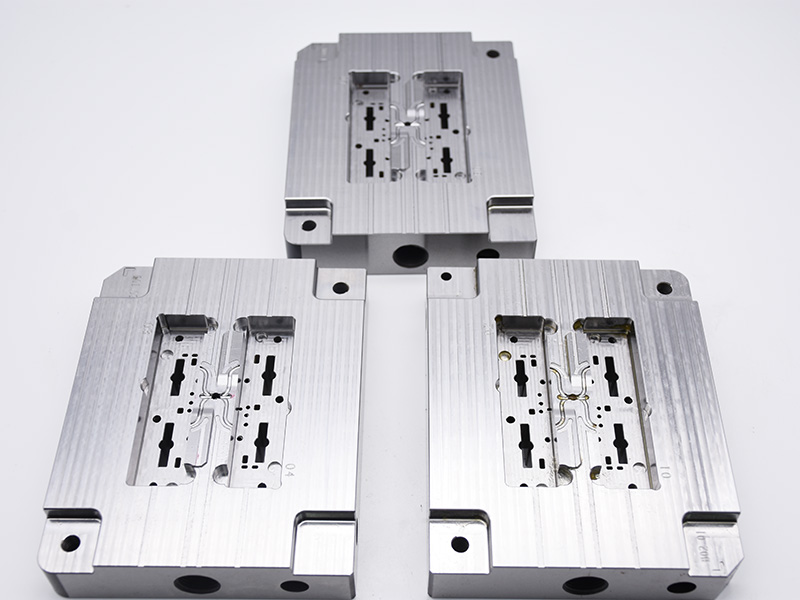

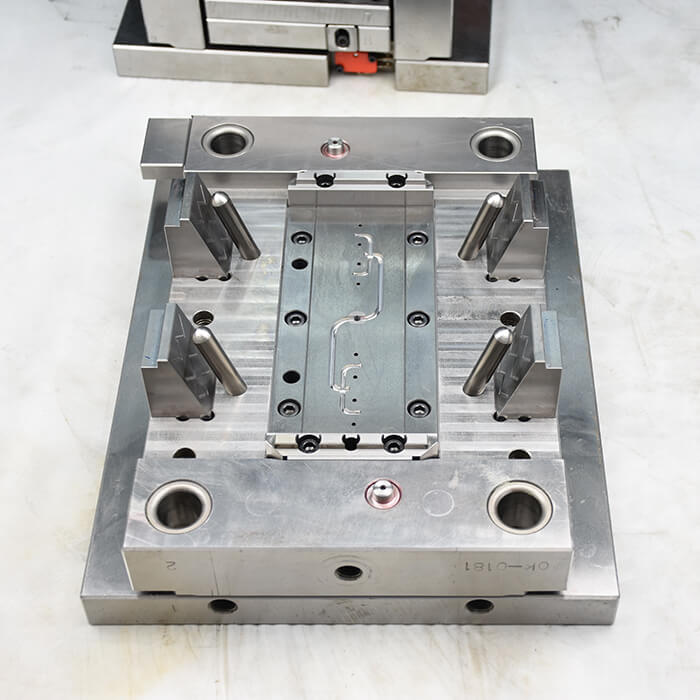

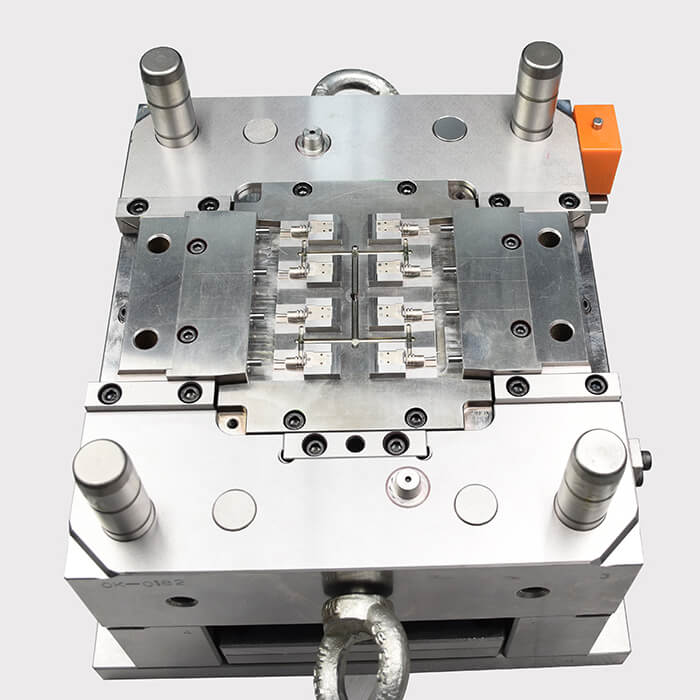

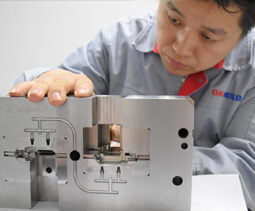

Precision Mold Cavity

Zefu mold specializes in providing customers with customized precision mold cavities with micron tolerance ±0.002mm.

WhatsApp

+86 18576732746

Welcome To Zefu Mold

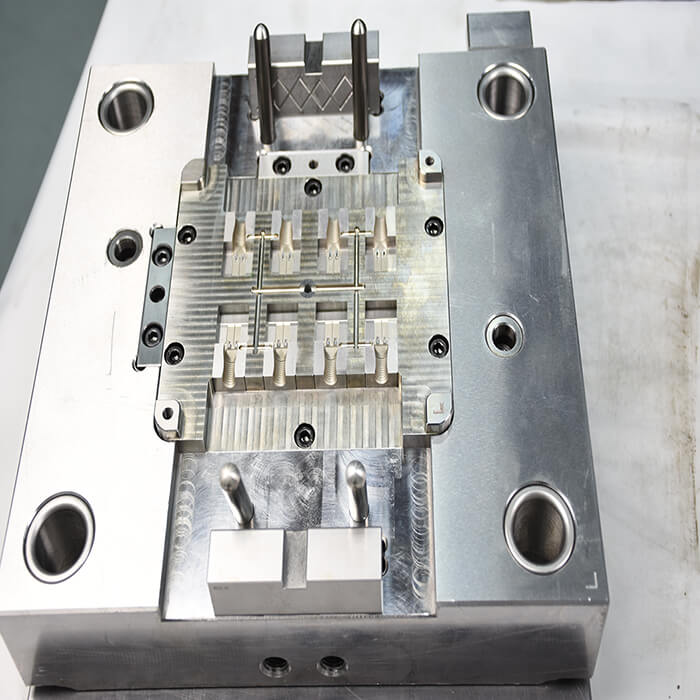

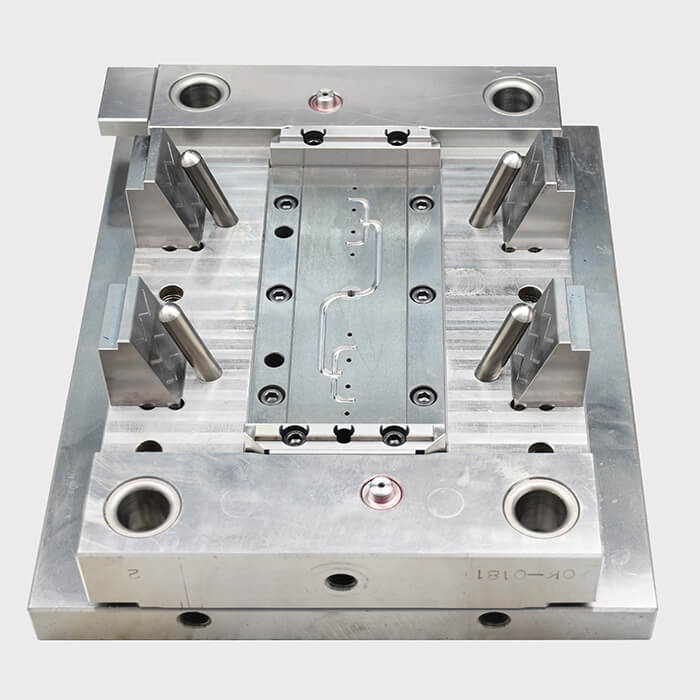

We’re Best Providing

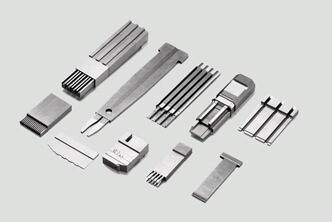

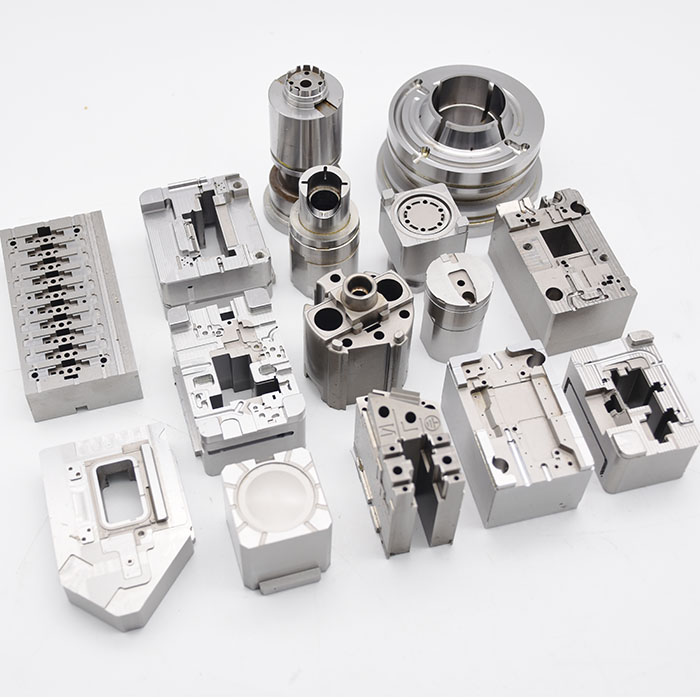

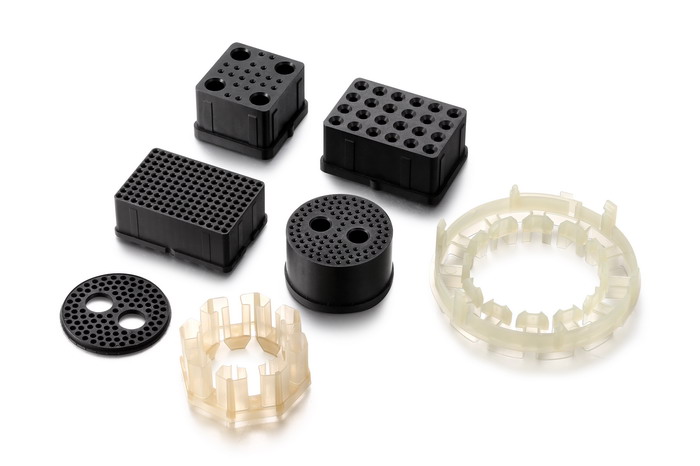

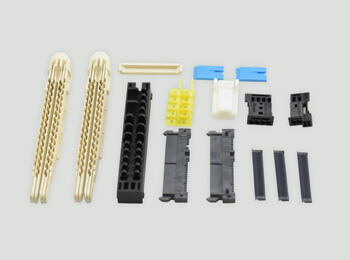

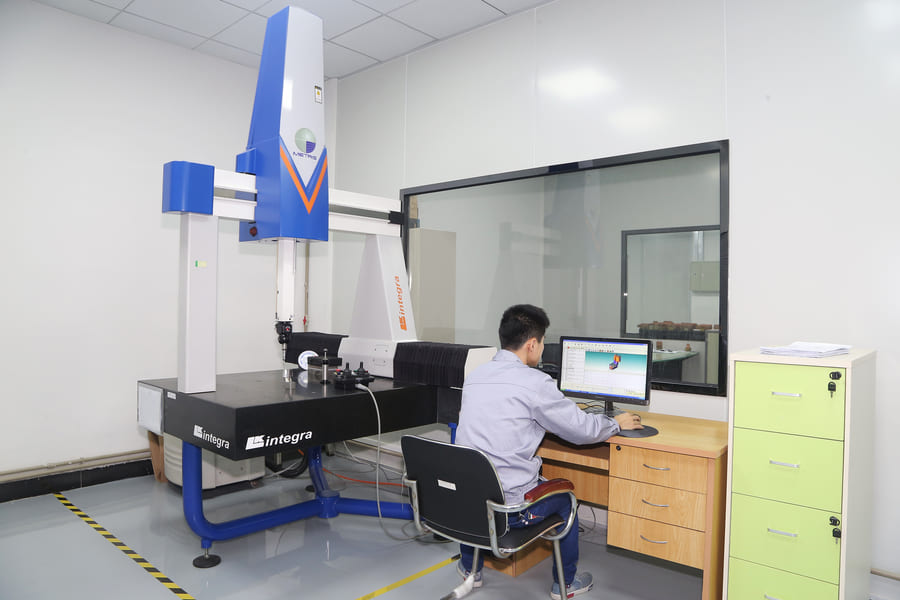

Precision Mold Spare Parts

Zefu mold supplies precision mold spare parts for global customers with one-stop solution.

WhatsApp

+86 18576732746